The clean energy transition will require lots of batteries — primarily to power electric vehicles and to store renewable energy that can be dispatched to the electric grid on demand. European Union policymakers are growing more concerned about where the bloc will get all the metals required to build those batteries. One potential source? Dead lithium-ion batteries from EVs, e-bikes, and consumer electronics, which contain lithium, cobalt, nickel, and other ingredients needed to make new ones.

Recycling the metals used in batteries has the potential to limit the need for environmentally damaging mining while also reducing electronic waste. But Europe’s lithium-ion battery recycling industry is in its infancy. While manufacturers sold nearly 700,000 tons of lithium-ion batteries into the European market last year, recyclers only had the capacity to process about 17,000 tons of battery waste, according to Circular Energy Storage, a data analysis firm for the battery industry.

New rules that entered force last month could help change that. After years of negotiations, the EU just adopted a comprehensive battery regulation that could spur battery recycling at a scale never seen before outside of China. Battery industry experts say the policy has the potential to supercharge lithium-ion battery recycling across the bloc.

The EU’s new battery rules “will make a very big impact for the whole supply chain not only in Europe but also globally,” Xiao Lin, CEO of the Chinese battery metal recycling consultancy Botree Cycling, told Grist.

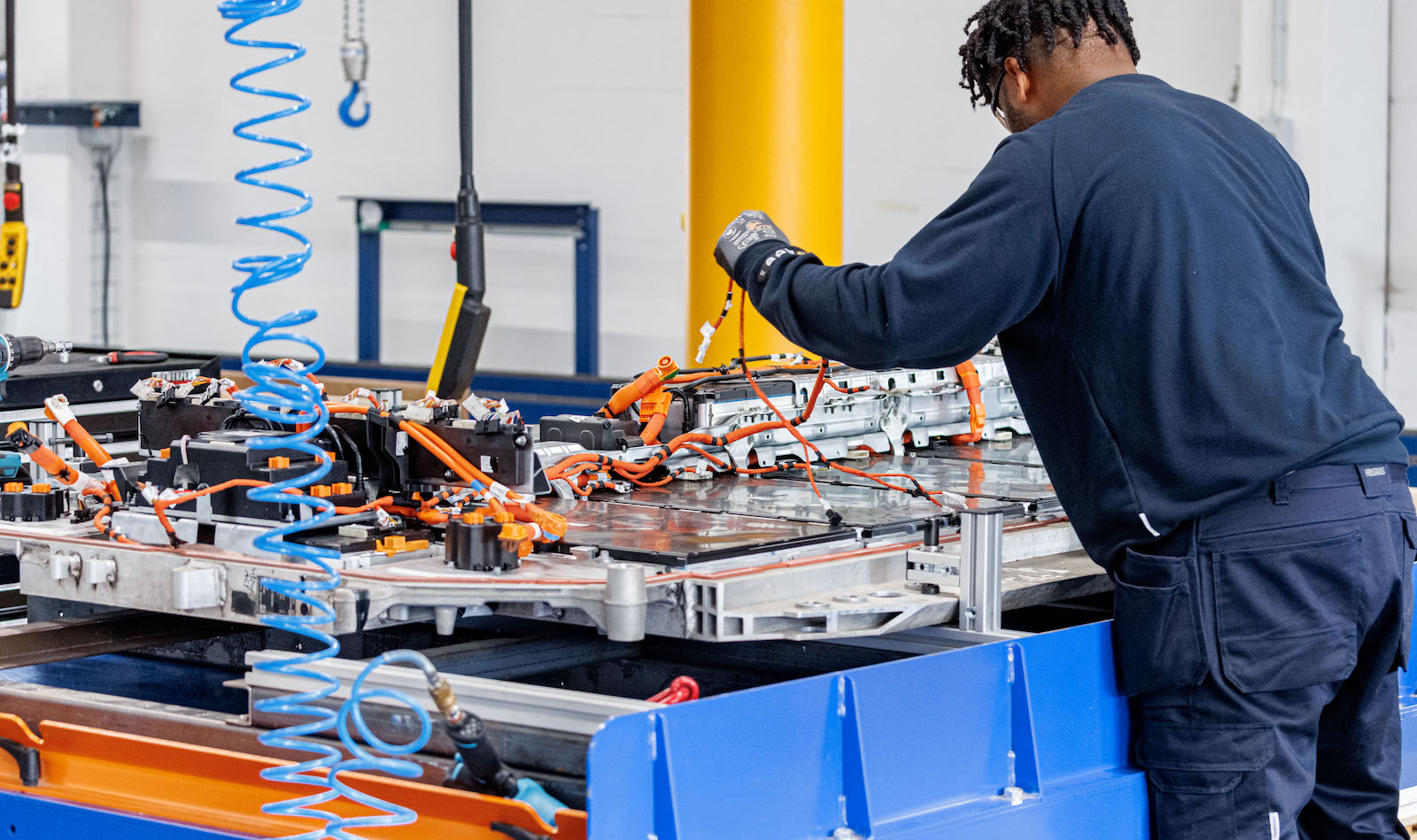

MATHIEW LEISER / AFP via Getty Images

The battery regulation replaces a 2006 policy that focused on minimizing the health risks caused by hazardous battery ingredients like lead and cadmium. The new rules reflect the larger role that batteries, particularly lithium-ion ones, play in society today, and the EU’s desire to ensure they are sustainable throughout their entire life cycle, from manufacturing to disposal. The regulation requires manufacturers to collect waste lithium-ion batteries for recycling and, in the case of EV, e-bike, and energy storage batteries, incorporate recycled materials into new ones. The battery regulation also includes ambitious metals recovery targets, pushing recyclers to use technologies that do a good job reclaiming critical resources like lithium.

The regulation comes at a pivotal moment. EV sales are booming in Europe and around the world, causing demand for the metals inside their batteries to skyrocket. Hundreds of new mines may be needed to supply those metals by the mid-2030s. But mining takes a significant toll on the environment, and often, local communities. Most EU nations have limited battery metal resources, forcing them to rely on imports from countries with poor environmental and human rights track records.

Battery recycling is often touted as a more sustainable way to ease long-term supply pressure. Spent EV batteries, as well as the smaller batteries inside e-bikes, power tools, smartphones, and more, are rich in the metals needed to make new ones. Today, China leads the world in lithium-ion battery recycling, thanks in part to policies that have encouraged it in the EV sector, specifically. In 2018, China’s government stipulated that EV makers are responsible for collecting dead batteries, and it set ambitious metals recovery rates that recyclers must meet to be included on a government white list.

The EU is now following in China’s footsteps by directing manufacturers to ensure that batteries are collected for recycling at no charge to consumers. For consumer electronic and “light means of transport” batteries — those used in e-scooters, e-bikes, and the like — collection rates will gradually increase over the next decade. In the EV and energy storage sectors, meanwhile, manufacturers are required to take back all batteries for recycling. Bosch, which manufacturers batteries for the European e-bike industry, told Grist in an emailed statement that bicycle makers have “either already successfully introduced or are currently working on collection systems” to meet the new requirements, with e-bike battery take-back programs currently up and running in Germany, the Netherlands, Belgium, and France.

Recyclers, meanwhile, are required to hit stringent metal recovery targets, including 80 percent of the lithium contained in a battery, and 95 percent of its cobalt, copper, nickel and lead, by the end of 2031. Alissa Kendall, a battery recycling expert at the University of California, Davis, says that these recovery rates will push recyclers away from pyrometallurgy, an older technique in which batteries are smelted in a furnace to produce a low-quality metal alloy. Instead, Kendall expects the new rules will accelerate the industry-wide shift toward hydrometallurgy. Hydrometallurgical recyclers typically shred batteries to produce a powder called “black mass,” then separate and purify individual metals using chemical solvents. While pyrometallurgical recycling often results in significant lithium losses, recyclers using hydrometallurgy claim they can recover lithium at high rates. There are also environmental benefits: While pyrometallurgy uses considerable energy and produces toxic gases that must be captured or remediated, hydrometallurgy requires less energy and generates lower emissions (although the strong acids involved require careful disposal).

“Our industry-leading, sustainable lithium-ion battery recycling technology is geared towards meeting lithium, cobalt, and nickel recovery targets set forth in the Battery Regulation,” a spokesperson for Canada-based battery recycler Li-Cycle told Grist in an email, adding that Europe’s regulations are “very positive for the growth of the industry.” Li-Cycle is one of several hydrometallurgical recycling companies in the process of massively expanding its presence in Europe: Last month, it opened a black mass facility in Germany and announced plans for a future recycling hub in Italy.

Recycling doesn’t have to take place in Europe as long as it meets EU standards. Lin says that many Asian recyclers are already meeting or exceeding the metal recovery rates in the European battery regulation. But Lin expects established recyclers will run into trouble with other EU standards, such as a requirement that 70 percent of the weight of batteries be recycled by the end of 2030. In China, about 65 percent of EV batteries sold today are lithium-iron-phosphate batteries, a chemistry that contains no nickel or cobalt. Aside from lithium, there’s very little in these batteries worth recycling. As a result, Lin says, recyclers are used to recovering about 3 percent of their materials by weight.

“It’s very different to reach 70 percent,” Lin said. Recyclers outside of Europe that want to cater to the EU market, Lin says, may have to set up new European facilities with more advanced technologies.

In addition to mandating efficient recycling, the new battery regulation seeks to ensure that recycled materials get incorporated into new batteries. By 2031, the EU will require that new EV and storage batteries contain at least 6 percent recycled lithium and nickel, 16 percent recycled cobalt, and 85 percent recycled lead. These figures will rise to 12 percent recycled lithium, 15 percent recycled nickel, and 26 percent recycled cobalt by 2036 (at which point they will also apply to “light means of transport” batteries). But while the intent of the recycled content standards is to promote the reuse of critical resources, experts warn that they could have unintended consequences.

Andy Leach, an energy storage analyst at consultancy BloombergNEF, says that if the recycled content standards are higher than what the recycling market can deliver on its own, companies might be forced to recycle batteries prematurely in order to reach them. Overly ambitious targets could also encourage battery makers to be wasteful, since the standards can be met with either end-of-life batteries or battery production scrap, which consists of cuttings and leftovers from the battery manufacturing process, as well as battery components that didn’t meet quality control standards. If there aren’t enough end-of-life batteries to meet the requirements, battery makers may be encouraged to keep generating large volumes of scrap, rather than implement efficiency improvements that reduce manufacturing waste over time.

“Recycling’s important, but we also shouldn’t rush into it if the materials aren’t there to be recycled,” Leach said.

Bosch, the e-bike battery manufacturer, called the recycled content targets “very ambitious,” adding that “the availability of recycled raw materials is the biggest challenge” to meeting them.

In particular, the achievability of the recycled content standards will depend on the return of heavy, mineral-rich EV batteries for recycling. But these batteries are long lived, and they are often repurposed for a second application like grid storage, meaning it could be years before large numbers of them are ready to be recycled. Li-Cycle told Grist that the company expects manufacturing scrap to represent “the bulk of our feedstock” over the next few years, with end-of-life EV batteries becoming more important in the 2030s. BASF, a German battery materials maker that is expanding its battery recycling operations, told Grist that it also “plans to recycle scrap” from battery production until more dead EV batteries are available.

While recycled content standards may encourage waste if they’re too aggressive, Kendall of UC Davis emphasized the importance of these standards for improving the economics of recycling. By placing a premium on recycled lithium and other metals, the standards could “increase the value globally for recycled materials,” she said. In a best-case scenario, that might help other emerging battery recycling markets become more economically viable over the long term. Those include the United States, where several companies are now building huge new plants to recycle EV batteries despite no federal mandates. (U.S. recyclers are, however, being supported by big federal loans.)

Despite uncertainties, many in the industry are hopeful that the new EU regulation will help battery recycling reach the scale needed to ease future mining pressure. Kurt Vandeputte, senior vice president of battery recycling solutions at the Belgian-based metals company Umicore, called the regulation “a smart way of saying that we have to be careful and we have to create a closed loop of critical materials.”

“It’s going to be the blueprint for many other industries,” Vandeputte said.