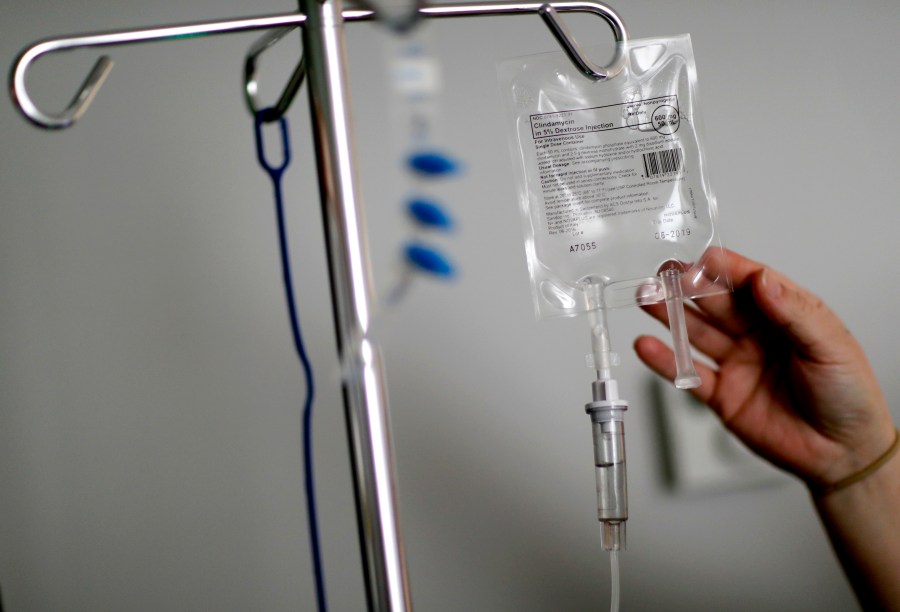

SIOUX FALLS, S.D. (KELO) — A factory that provides IV fluid bags all over the United States is beginning production again, but while the factory is back in action local health leaders say it could still take a couple weeks for health providers to get back to normal.

Baxter International supplies 60% of the country’s IV fluid bags. Baxter’s North Cove manufacturing site in North Carolina was significantly impacted by the rain and storm surge from Hurricane Helene and resulted in water flooding the facility causing it to close.

According to a post on Baxter International’s website, employees are returning to work at pre-hurricane staffing levels at the North Cove manufacturing site, working alongside remediation contractors that have been engaged on a temporary basis for site recovery.

Local health providers in Sioux Falls said the IV shortage is still very much ongoing.

“While Sanford Health didn’t experience any significant shortages of IV fluids in our hospitals and clinics following Hurricane Helene, many health care systems across the country experienced severe shortages,” a Sanford statement to KELOLAND News said.

“As these shortages will likely have local and national implications for the next several months, we continue to follow conservation efforts and monitor supply to help support those that are still experiencing shortages. We did not postpone any surgeries, including elective surgeries, due to shortages in IV fluids,” the Sanford statement said.

Vice President for Avera Medical Group Clinical Quality, David Basel, said while Baxter has people back working in the factory, they are still in the early stages of getting IV fluid supplies back to normal.

“This is a multi-week process before we will start to see fluid hit the market or hit the docks here locally,” Basel said. “We are still several weeks off from that starting to loosen up from what it is. So are the lines starting back up? Yes, but it’s a long process before we actually see any of that get here.”

Basel said it will take time for the factory lines to get FDA approval and start sending out IV bags.

“As we understand it, it’s going to be a line-by-line process and they get the line up and running and then they have to get FDA approval before they are able to start selling it and then it has to start getting into the shipping lanes,” Basel said.

Basel said while the situation does require additional management from them, it’s not disrupting patient care.

“The good news is we have been able to manage the situation pretty intensively so we aren’t having to cancel cases, we’re just in kind of a management situation,” Basel said. “We will take 1 liter of fluid and divvy it up into multiple smaller bags so that any type of use case that requires a smaller bag we don’t use a whole liter bag.”

Basel said one of the biggest problems they have had is keeping up with current information, stating that it’s a very fluid situation to discover what’s available out there in terms of supplies.

Basel said they are monitoring their supply lines and managing their current supplies, stating they are still several weeks out from being back to normal.

“Right now it’s really a matter of matching week to week of what’s available on the market and making sure it’s meeting our needs,” Basel said. “We have been really fortunate, we have some great supply chain people, great pharmacy people to make it so we can adjust our usage without affecting clinical care.”